Pool Equipment Installation Alpharetta & Cumming, GA

Elevate Your Pool Experience With Pool Filter Installation in Alpharetta

Filter systems play a crucial role in maintaining the crystal-clear water of your pool by removing debris through a filtration media. Understanding the different types of filter systems is key to achieving the best water quality for your swimming pool.

- Cartridge filters function similarly to a coffee filter, utilizing corrugated paper or polyester cloth to capture debris. These filters are easy to clean with a hose but require replacement when worn or damaged, typically every other year for seasonal pools or annually for those in use year-round. It’s wise to keep a spare set for seamless maintenance.

- Sand filters operate by trapping debris within the sand as water percolates through—thanks to gravity. This method effectively captures fine debris but requires backwashing 1–2 times weekly to maintain efficiency. The sand should be replaced every 4–5 years to ensure optimal performance.

- For those seeking unparalleled filtration, DE filters use diatomaceous earth derived from fossilized sea organisms to trap even the finest particles. This system coats filter grids with DE, allowing water to pass through and debris to be ensnared by the DE layer.

Whether you’re considering a pool pump installation in Cumming, upgrading with a pool pump and filter installation in Alpharetta, or enhancing comfort, Luke Pools is here to ensure your pool remains a pristine oasis for relaxation and fun. Trust us to provide quality pool heater installation in Alpharetta services.

Elevate Your Pool Care with Pool Equipment Installation in Alpharetta

At Luke Pools, we believe in combining effective chemical treatments with state-of-the-art filtration to achieve a pool environment that’s not just safe and healthy but also fully compliant with all swimming pool regulations. Our skilled technicians are adept at navigating the myriad options for pool treatment, from straightforward chlorine feeders to the more complex, automated systems that include salt chlorine generation.

Chemical Feeders

When it comes to maintaining your pool’s pristine condition, chemical feeders are indispensable. They precisely inject sanitizers or chemicals for pH adjustment directly into the pool via the filter system’s return line. Whether you prefer manual control or the convenience of automation, we have the solution that fits your needs.

Peristaltic Pumps

Efficiently transport liquid chemicals from their containers to the pool, ensuring a constant flow of sanitizing agents into your swimming environment.

Erosion Feeders

Are your go-to for a steady dissolution of solid chemical tablets, like trichlor or bromine, providing a long-lasting sanitization effect that requires minimal intervention, save for the occasional refill.

Salt Chlorine Generators

Use trichlor or bromine in the form of a dissolving tablet. Over time, they need to be refilled.

Ozonators

offer a powerful, chemical-free option to obliterate bacteria, but they lack the residual effects monitored by health departments and, thus, are not solely recommended for commercial pools.

Whether you need a pool pump installation in Cumming or looking to upgrade your pool’s entire system with pool equipment installation in Milton, Luke Pools is your trusted partner. Our commitment to excellence and detailed attention ensures that your pool remains a sparkling oasis of enjoyment for you and your loved ones. Let us handle the technicalities so you can dive into the sheer joy of swimming.

Pump and Motor Systems

The heart of a swimming pool’s circulation system lies in the pump and motor duo. The motor powers the pump, which orchestrates water flow from the pool’s skimmer and drains through the filter to capture and remove debris. This cycle might also include heating the water for enhanced comfort before it circulates back into the pool. To ensure your pool meets health standards and maintains its allure, selecting the right size for pumps and motors is crucial. Our skilled technicians are adept at conducting detailed assessments, including flow calculations and pump curve reviews, to provide personalized and efficient solutions.

When it comes to motor speed, there are three options:

Single-speed motors

Which operate at a constant velocity, are simple but fall short on energy efficiency since their speed can’t be adjusted to the pool’s varying needs.

Two-speed motors

Step up the efficiency game, providing options for high or low-speed operation, giving you more control over energy use and operational costs.

Variable-speed motors

Are at the forefront of energy conservation, allowing for fully customizable pump speeds tailored to the specific requirements and activity patterns of your pool.

The choice of motor is dictated by the pool’s size and the necessary turnover rate to comply with health regulations. It’s essential to align the pump’s motor horsepower with the pump type and desired flow rate to avoid overpowering the system. An overly robust motor could lead to filtration challenges and potentially harm filters and heating components. Proper system design is critical, ensuring the filtration setup matches the dynamic flow produced by your pump and motor while keeping your pool pristine and inviting.

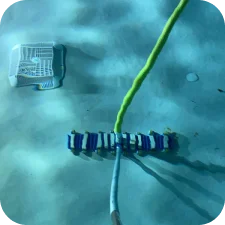

Leak Detection and Repair Services

Leaks in a pool can arise from various factors, including winter damage, equipment malfunction, the age of the facility, and construction quality. Without proper attention, a leaking pool can squander thousands of gallons of water daily, significantly impacting water and chemical usage and risking further structural damage. Our team of leak detection and pool repair in Alpharetta & Milton works closely with pool owners to pinpoint leaks and deploy effective repair strategies, ensuring the longevity and safety of your pool.

The process of detecting leaks is methodical and thorough:

- Initial Consultation. Engaging in a conversation with the pool owner or operator is crucial for gathering initial information about the pool’s history and the extent of water loss, which guides our experts in identifying potential leak sources.

- Visual Inspection. A comprehensive visual assessment offers additional insights into the pool’s condition, supplementing the information collected during the consultation.

- Non-invasive Testing. We employ various tests, such as Static Tests, Bucket Tests, and Dye Tests, in collaboration with the pool owner or manager to locate leaks not associated with underground plumbing.

- Pressure Testing. For underground plumbing issues, we conduct pressure tests on individual pool lines, monitoring for pressure loss or stability to identify leaking lines. Advanced tools like listening devices, cameras, and helium testers may be utilized to pinpoint leaks accurately.

- Tailored Repair Solutions. Upon completing the assessments, our experts compile a detailed report and recommend effective repair strategies. For extensive issues, temporary solutions might be proposed to extend pool usage until the off-season, when comprehensive repairs can be undertaken without time constraints, allowing for a thorough resolution of any complex challenges.

Maximize Your Pool Season With Efficient Heating Solutions

Elevate your pool experience and extend its usability into the cooler months with a pool heater or heat pump installation. We offer various heating options, including natural gas, propane, electric heat pumps, and eco-friendly solar heating systems to maintain a pleasant pool temperature. When choosing a heating system, it’s crucial to consider codes, safety, and efficiency.

Gas Heaters

For rapid temperature increases during the early and late pool season, gas heaters are highly effective. These heaters operate by burning natural gas or propane in a combustion chamber. Propane heaters require a refillable fuel tank. While gas heaters are more affordable to install than heat pump filters, their lower efficiency might lead to higher operational costs over time.

Heat Pumps

Ideal for maintaining a comfortable water temperature over longer periods, heat pumps are more gradual but energy-efficient. They draw heat from the air and transfer it to your pool’s water, remaining effective in air temperatures above 50ºF. Despite higher initial costs, their operation is more cost-efficient, making them a budget-friendly option in the long run.

Solar-powered Heaters

Harness the power of the sun to heat your pool with solar-powered heaters. Water is circulated through heating elements by the pool’s pump, operating during daylight hours to optimize energy use. Their effectiveness is weather-dependent, with peak performance under sunny conditions.

Leak Detection and Repair

Begin the season with our comprehensive service, including cover storage, filtration inspection, and pool cleaning. We ensure the chemical balance is perfect and alert you to repair needs.

Closing & Fall Winterization

Prepare your pool for winter with our thorough winterization service, protecting your equipment’s longevity. We manage everything from chemical adjustments to covering your pool.

Summer Maintenance Plans

Choose our tailored maintenance plans for a worry-free pool experience. Our services, including cleaning, filtration maintenance, and chemical balance checks, come with an Algae-Free Guarantee.

Winter Service

Ensure your pool’s durability through the winter months with our specialized service, mirroring our fall winterization to safeguard your investment year-round.

Our Portfolio

Over the last 16 years we’ve worked on thousands of pools. We’ve accumulated the know-how, experience, and expertise to readily put to your service. Browse our portfolio to see what’s possible for your pool. Together, we’ll turn your ideas into reality.

FAQs About Pool Equipment Installation Alpharetta & Cumming, GA

How do you install pool equipment in Alpharetta?

In Alpharetta, installing pool equipment involves carefully assessing your pool’s needs, selecting the right equipment for efficiency and compliance with local codes, and professional installation by trained technicians to ensure optimal performance and safety.

What types of pool equipment do you install?

We install a variety of pool equipment, including pumps, filters, heaters, and automated cleaning systems tailored to enhance your pool’s functionality, comfort, and maintenance ease.

Can you assist with pool pump installation in Milton?

Yes, we can assist with pool pump installation in Milton. Our services include evaluating your pool’s requirements, recommending the best pump type for your needs, and ensuring a professional installation for efficient water circulation.

Do you offer pool heater installation services in Alpharetta?

We offer pool heater installation services in Alpharetta, providing a range of heating solutions like gas heaters, heat pumps, and solar heaters to extend your swimming season with comfortably warm water.

What is involved in pool filter installation?

Pool filter installation involves selecting the appropriate filter type for your pool’s volume and usage, professionally installing the filter to ensure it effectively removes debris, and integrating it seamlessly with your pool’s existing circulation system.

Our Customer Say

We take pride in the relationships we build with our customers. Their reviews speak for the quality of our work and encourage us to keep aiming for perfection.